If you are running a woodworking workshop or even thinking of adding a table saw in your workshop then this article is the best for you. In this article, we will discuss how to get the most out of the table saw.

Table saw is one of the most used woodworking shop tools, which is why you need to know the guidelines for using it.

Tips and Tricks to Use Table Saw in Workshop

These are the best tips and tricks you can find for using a table saw in the workshop for woodworking. Use the following guidelines and make the most out of a table saw. Before getting started you need to know a little bit before choosing a cabinet table saw for working within your workshop.

Using table saws for woodworking

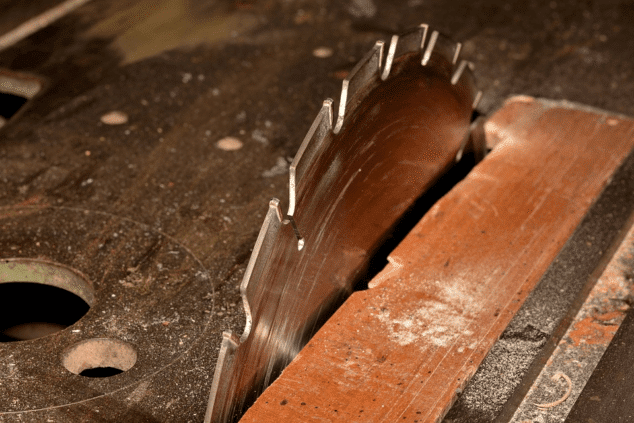

Table saw is a kind of workhorse for the workshop of the woodworking. It is the most used tool and it is a highly productive tool for woodworking. By using this single tool, you can easily cross cut, dado, rabbet, rip, miter cut, and can be used for creating shapes on the edges of the wood.

You can get to learn about various features of using a table saw from different sources, or you can try visiting Firstwoodworker.

Safety tips for table saw

Even the tables are the most productive tool available in the workshop of woodworking, but it is still considered as the most dangerous tool. Many of the woodwork events lost their fingers, hand or even worse. In order to reduce hazards in your workshop, you should definitely use safety precautions which will decrease the chance of injury. As woodworking requires using dangerous tools, it is better to be safe and take precautions or it may end up badly.

Tuning up the table saw

To make your table saw work smoothly, it needs to be kept in regular maintenance. A maintained table saw can be used mostly in any manner without any issues. Non maintained table saw will end up having issues and it is far more dangerous to operate. Table saw tends to bind if it is not kept in proper maintenance on a regular basis. There are several basic steps which can be taken for tuning of the table saw. This is the best way to increase productivity and decrease the chance of hazards in your workshop. So regularly clean it and maintain for availing its services for a longer period.

Keep the table saw rust-free

If you have chosen the best quality of table saw which is well built and equipped into a table which is made from cast iron, then it may end up in rust. The main reason for using the cast iron for building the table is that the weight of the cast iron gives the stability to the saw while using it. By Nature, bare cast iron will get rust on it as it may end up discolouring the wood. You can even have difficulty while using the tables if it is rusted.

Dado blade stacking

Rabbet and Dado cutting is mainly done by the table saw. There are two types of dado blades available for table saw, you can either use a single blade or you can get the stacked blade. They are used for specific angle or adjustments in order to complete the cutting of the woodworking. You need to set up the stacked dado blade which needs to be set over on wobble blade. You need to follow the safety precautions for setting up the blade in the table saw.

Stacking up dado blades on small table saws

Not each and every table of the table saws are large in size, few of the table saws are available in small portable sizes too. In most of the cases, it has a small area for setting up stacked dado blades. Although you need to keep in mind while purchasing any small table saws which ones can be used for stacking up dado blades.

Jointer Jig of the table saw

Jointer in the table saw is used for straightening the edges of the board. It is considered as a speciality tool but still, it does not have multiple uses in the table saw. In case your table saw is not having jointer jig, then you can make on your own by using woodworking plans. Basically, most of the woodworkers only use it for straightening the edges of various boards.

Box joint jig on the table saw

Box joint jig is much useful although it is less used for dovetail joints. The dovetail joint is the best alternative to the box joint which is not much used since it was introduced. Dovetail joints are more compact compared to the box joint, still, you will find several box jigs in table saw. You need to keep in mind that joining the pieces of wood is rather difficult if compared with creating any woodwork. You can easily cut out box joint using any simple jig and your table saw. Although it is still used in most of the workshops what the box joins according to the requirements of the client.

Tapering Jig on the table saw

Most of the furniture woodworking products required to have tampered legs. It is mostly used for the legs of tables or chairs. Although tapering legs are cut out by hand and it is the simplest way of connecting pieces of wood.

Last Words

Table saw is the biggest tool which is used by the woodworker in their workshop. This is one of the modern tools which is used by almost each and every woodworker. We have gathered complete information about the tables and its uses from various sources and posted them this article for you. Share this article with others, so that they can also get to know about the complete usage of the table saw.